The video explores former President Trump’s efforts to bring AI and advanced hardware manufacturing back to the U.S. by demanding full domestic production, challenging global supply chains dominated by countries like China. It highlights the strategic importance of building a robust, onshore manufacturing infrastructure for future AI devices, while humorously considering unconventional solutions like creating a new country dedicated to AI development.

The video discusses former President Trump’s recent push to reshape the global technology supply chain by demanding that major companies like Apple manufacture their products entirely within the United States. Trump’s efforts go beyond just relocating existing manufacturing footprints; he is advocating for full fabrication capabilities domestically. This move is part of a broader strategy to bolster American manufacturing, especially in the context of the rapidly advancing field of artificial intelligence (AI) and physical technology. The goal is to ensure that the U.S. remains competitive in developing next-generation devices and AI-powered hardware.

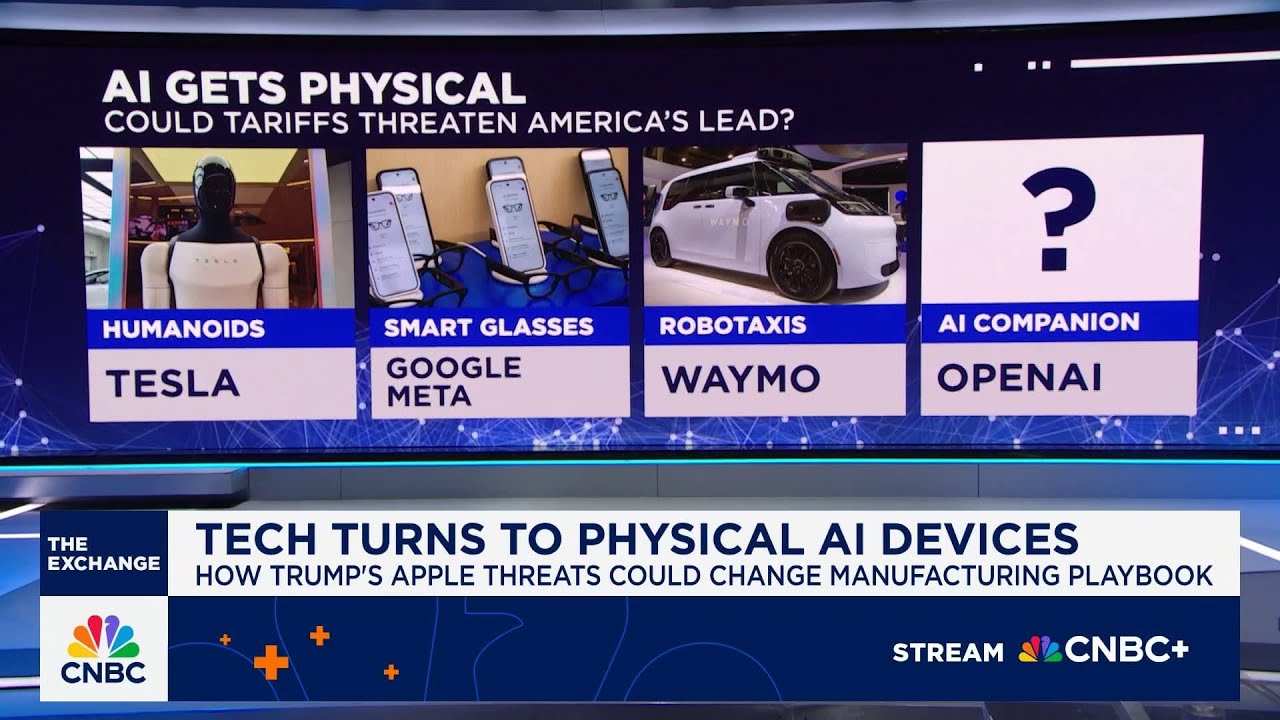

The conversation highlights that the future of AI and related technologies is increasingly physical, involving not just software and models but also hardware like smart glasses, humanoid robots, and autonomous vehicles. These innovations require substantial manufacturing capacity, which is currently concentrated in countries like China and Vietnam. Trump’s push for onshoring could challenge this global supply chain, potentially delaying or complicating the development and deployment of cutting-edge AI devices in the U.S. If the U.S. cannot meet these manufacturing demands, it risks falling behind in the global race for technological dominance.

Apple, which has historically moved much of its supply chain to Asia, is at the center of this debate. During the first Trump administration, Apple adapted to the shifting landscape, but the stakes are now higher with the rise of physical AI devices. The question arises whether Apple or similar companies can meet the new demands for domestic manufacturing. If they cannot, it raises concerns about who else might be capable of fulfilling these needs, especially as other countries like China continue to develop their own AI and hardware capabilities.

The discussion also touches on the challenges of building a robust manufacturing infrastructure in the U.S., including regulatory hurdles, costs, and red tape. While established companies like Apple have extensive supply chains abroad, newer AI-focused companies like OpenAI might have the flexibility to start fresh and build domestically from scratch. However, the high stakes and existing complexities make this a daunting task. The conversation suggests that creating a fully domestic supply chain for advanced AI hardware is a significant challenge but potentially necessary for maintaining technological leadership.

Finally, the speakers humorously speculate about unconventional solutions, such as establishing a new country or offshore platform dedicated solely to AI manufacturing—like the fictional idea of a nation on an abandoned oil platform off the coast of England. They joke about the possibility of creating a separate jurisdiction for AI development, free from regulatory constraints, to bypass the hurdles faced in the U.S. and other countries. Overall, the discussion underscores the strategic importance of manufacturing capacity in the AI race and the potential implications of Trump’s policies on the future of tech innovation.